Morgui's team of engineers has developed different products to offer solutions tailored to the needs of each professional kitchen.

Water-Based Grease Filtration in Industrial Kitchen Smoke Extraction

Water as a filtration element

Water filtration is particularly effective in smoke extraction systems handling fumes from embers, whether wood- or charcoal-fired, where combustion generates high concentrations of soot, carbonaceous particles and grease compounds in suspension. These contaminants, in addition to soiling ductwork and equipment, can compromise system performance and significantly reduce the service life of the fan.

The operating principle is based on particle capture through contact with a water curtain or film. As the air passes through the wet zone, soot and solid particles are retained by impact, inertia and washing effect, increasing their mass and promoting their separation from the airflow. In this way, the load of suspended solids is drastically reduced before the air reaches the impeller.

Furthermore, water filtration improves the hygienic and sanitary conditions of the system, reduces the risk of flammable build-ups within ductwork, and facilitates compliance with regulatory requirements in catering facilities and commercial kitchens. In demanding applications, it can be complemented with additional separation or filtration stages to further optimize the overall performance of the extraction system.

HIDRO exhaust hood

The HIDRO exhaust hood is specifically designed for barbecues, volcanic lava stone or charcoal embers, rotisseries or chicken roasting ovens, or any application where high temperatures are generated that may affect the extractor, as well as in kitchens with high grease or residue production.

This hood is manufactured with three filtration stages:

Stage 1: designed to filter grease by means of refrigerated filters, achieving higher condensation efficiency and reducing the temperature of the air reaching the extractor.

Stage 2: designed to separate moisture or droplets that may be drawn in by the fan. The spray nozzles create a uniform water curtain. Water consumption is 0.3 l/min per nozzle at 2 bar pressure, without the need for a pressure pump.

Stage 3: designed to separate water droplets by means of 490x400x25 mm filters.

Wet Filtration Module (MFVH)

The Wet Filtration Module (MFVH) is specifically designed for the separation and filtration of residues generated in wood- or charcoal-fired ovens. It is intended to be connected to the smoke extraction ductwork just upstream of the ventilation box.

It consists of three distinct stages:

1. Filtration of larger soot particles by means of a plate filter. It also prevents the backflow of water droplets from the spray nozzles in the event that the extractor is not started.

2. Mesh filter to collect impurities contained in the extracted air. The filter is fully saturated by the spray nozzles, retaining any impurities or grease that may remain airborne.

3. Droplet separator plate filter to prevent water droplets from being discharged through the air outlet. It is supplied with a liquid collection tray with drain connection, which must be connected to a grease or sludge separator to prevent direct discharge into the sewage system.

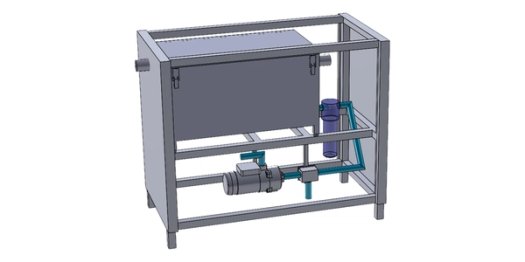

Water Recirculation Unit

The Water Recirculation Module is a complementary system to the two previous units, enabling substantial savings in both energy and water consumption.

How does it work?

Through mechanical filtration and decantation, this module allows the reuse of water from grease filtration systems via sprayed water (Hidro extractor hood or wet filtration modules).

This recirculation module features a grease separator as its central element. Water enters the separator through an elongated deflector, which ensures a slow and even distribution of the incoming flow. Fats and oils separate and rise to the surface due to gravity. During operation, a floating layer forms and increases in thickness, and when the maximum storage volume is reached, the fats must be removed.

A level sensor monitors the grease separator capacity according to established limits. The recirculation system mixes fresh water with filtered water from the hood via a 3-way valve. At the same time, the pump sends water back to the filtration system.

It can be complemented with a control panel that includes control and regulation commands, potentiometers, and indicator lights for operation, fault, and cleaning, and optionally frequency inverters for water pressure control. This control panel makes the system even more efficient.

If you are interested in any of these solutions, please do not hesitate to contact us. We will be pleased to provide further information and present some of the projects that are already in operation.