Morgui ventilated ceilings are designed for professional kitchen installations where smoke and vapours need to be captured over large surface areas.

Ventilated ceiling at Barcelona Culinary Hub

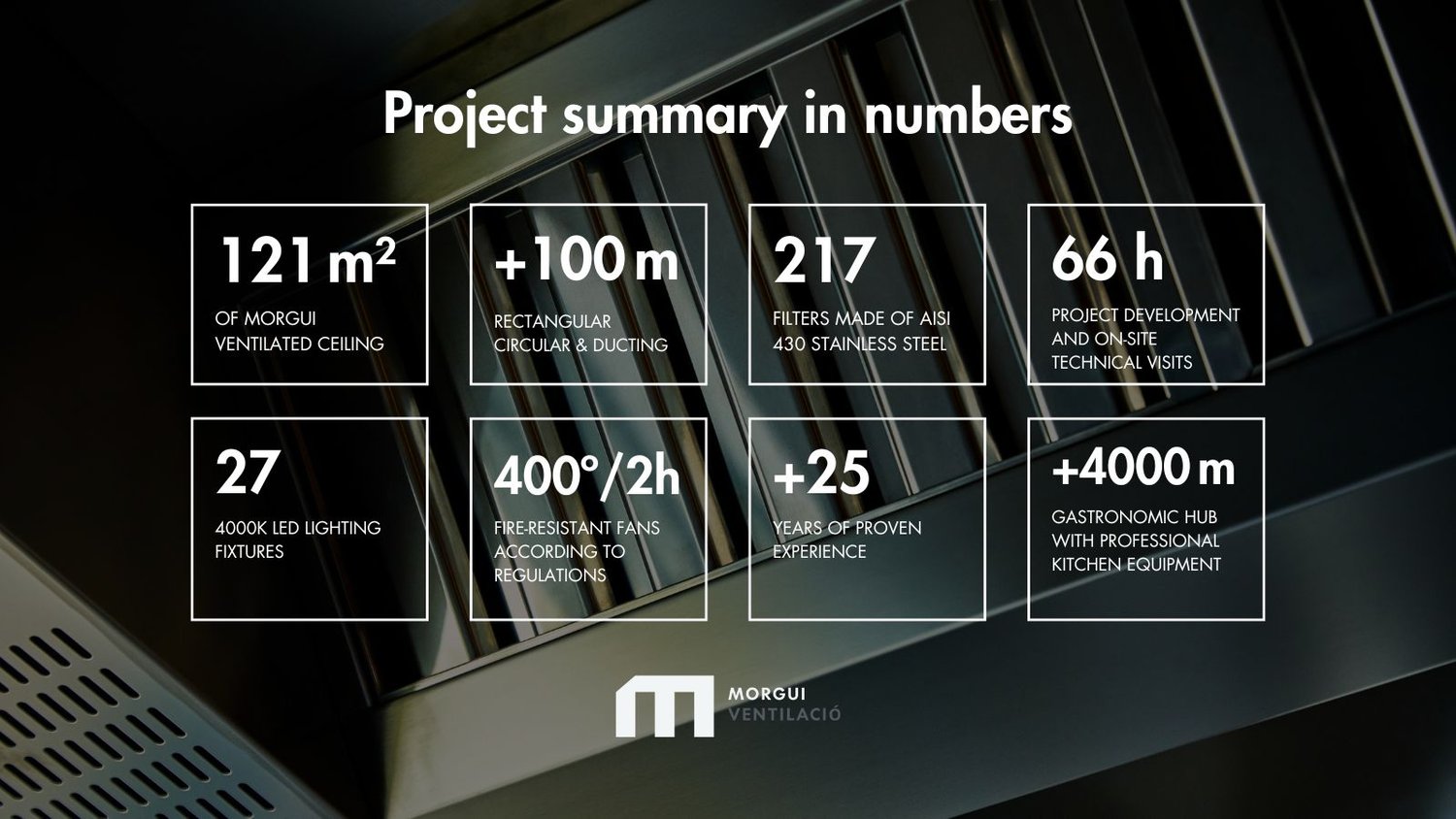

The new higher gastronomy school in Barcelona features over 121 m² of Morgui exhaust ceiling.

We present one of our most successful projects of 2022: the smoke extraction system design for the new BARCELONA CULINARY HUB.

This school is part of the international higher education network of Grupo Planeta and is affiliated with the University of Barcelona. Its foundation is built on innovation, culinary training and research, sustainability, and creativity.

Its teaching methodology is based on “learning by doing”, which makes practical training classrooms essential. That’s where we came in — by manufacturing over 121 m² of filtering ceiling and delivering the complete smoke extraction system for these classrooms.

Below, we explain how we did it, step by step.

1/ Phase One Project study and evaluation

In this initial phase, we focused on analysing the project's needs and assessing the condition of the building alongside other key stakeholders: architects, engineers, and the client.

The school features two classrooms designed for training and practical work with professional hospitality equipment. Both spaces required an industrial smoke extraction system that could cover large cooking areas while ensuring visibility, mobility, and comfort for both students and instructors.

The decision to install a Morgui ventilated ceiling was driven precisely by the need to ensure optimal smoke extraction without compromising those conditions, and because the kitchen production would not involve high-performance cooking generating excessive smoke, grease, or soot.

Once the final proposal was approved, the Morgui team got to work. We relied on the professionalism of our specialized technicians and our proven know-how backed by over 25 years of experience — as well as a previous project with very similar characteristics: the University Centre for Tourism, Hospitality and Gastronomy in Barcelona (CETT-UB).

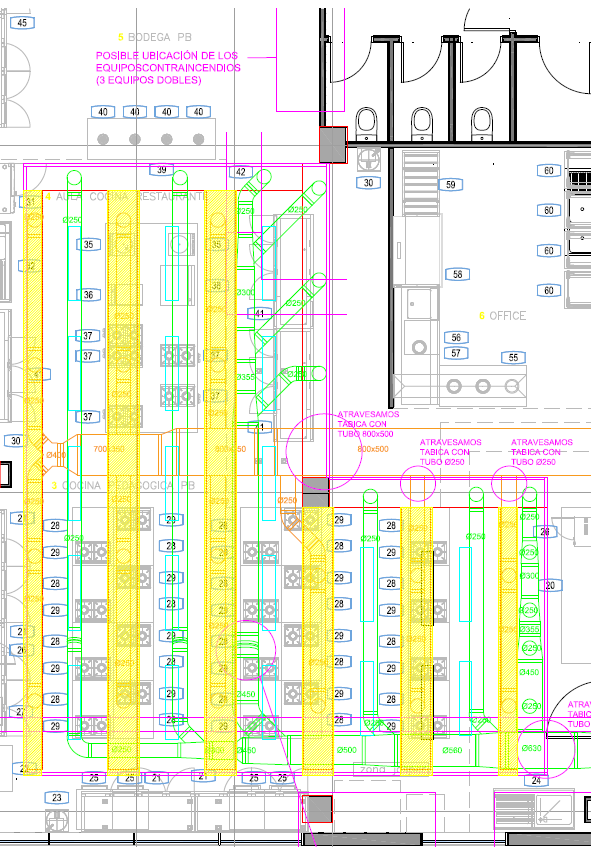

2/ Second Phase Design and Drafting

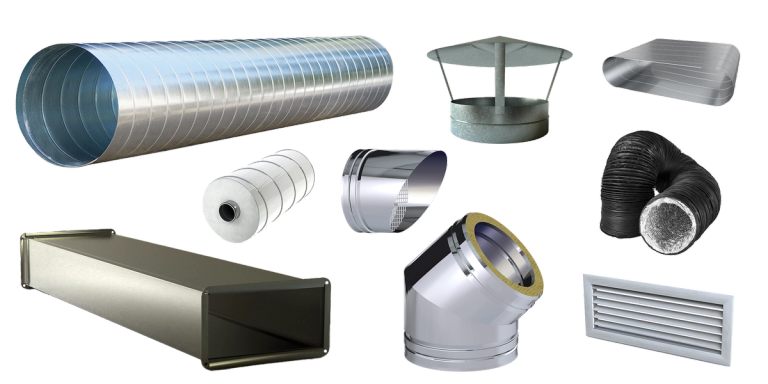

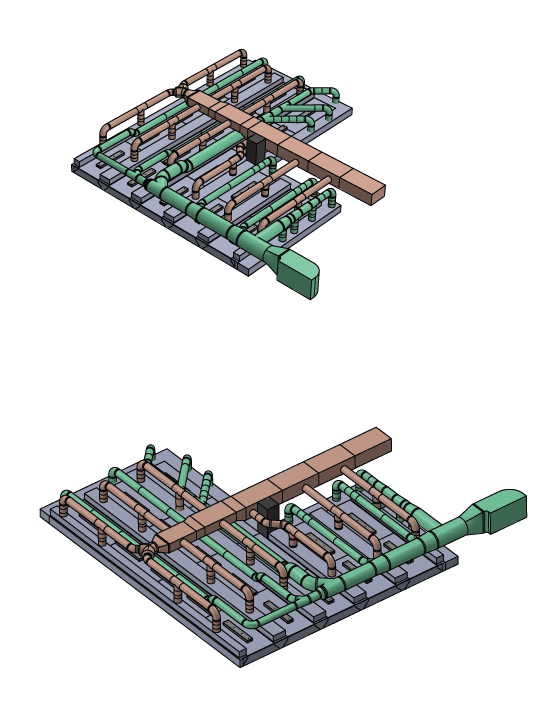

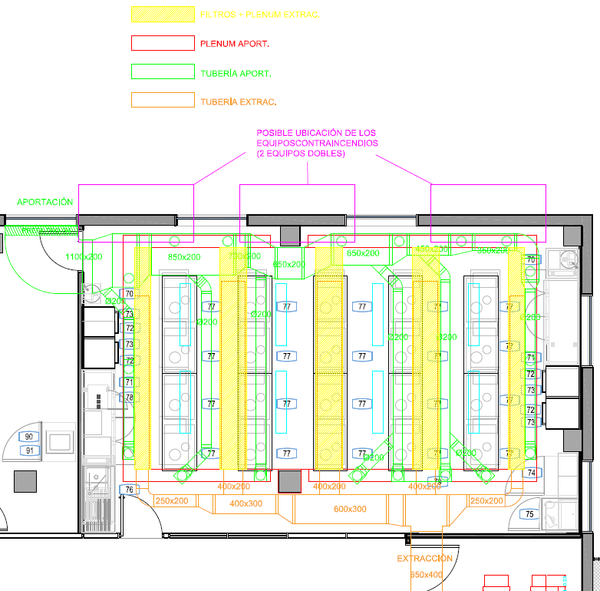

The second phase focused on the precise design of the ventilated ceilings and, in particular, the entire ductwork system, especially in the main room where the gastronomic lab is located. This room alone included 77 m² of Morgui ventilated ceiling and a carefully calculated network of extraction and air supply ducts, all in compliance with EI30 fire sectorization regulations.

Similarly, the design and airflow calculation were also carried out for the pedagogical classroom on the first floor, covering a total surface area of 44 m².

At this stage, coordination with the project’s engineering team, architects, and construction company was crucial. The outcome of this collaborative work and strict adherence to all technical requirements greatly facilitated the process—particularly the design and installation of both circular and rectangular extraction ducting.

3/ Third Phase Manufacturing and Installation

The third phase involved the manufacturing and installation of all products and components.

Over the course of 5 weeks, the ventilated ceilings were built using 1 mm thick AISI 304 stainless steel. The configuration consists of central or perimeter modules, each 310 mm in height, with individual, serviceable plenums.

The filter collectors include a total of 217 AISI 430 plate filters with anti-cut protection, measuring 490x250x25 mm, and grease collection trays along all filter lines.

The installation also includes 19 LED lighting fixtures measuring 1200x250 mm, with 4000K light temperature and IP54 protection, along with three-level fire suppression systems and a detection line with fusible links.

Once the ventilated ceilings were completed, the smoke extraction ventilation boxes were installed—essential components of the system. In this case, two Morgui-branded UNIC 400 ventilation boxes were produced: a 30/14 unit with 15 HP for the main classroom, and a 25/13 unit with 10 HP for the training room on the first floor. Both units are equipped with single-inlet centrifugal fans, belt-driven motors, emergency trip switches with IP65 protection, and JET exhaust hats sized 800 and 710.

For system control and regulation, two Invertek variable frequency drives were installed. These units have three-phase input and output (380 V), IP66 protection, and power ratings of 11 kW and 7.5 kW respectively. Two OPTIPAD digital potentiometers were also installed to allow remote control of the extraction system.

4/ Fourth Phase Commissioning and Handover

Finally, we reach the last phase: commissioning and handover of the project.

After nine months of work, design, assembly, manufacturing and technical visits, we can now see this major project completed. It’s a true source of pride to share a result that is both visually and functionally rewarding.

Today, both training areas are fully operational, helping to shape the future chefs and professionals of the hospitality sector.