We present the kitchen of the König restaurant in Blanes. The chain, with over 50 years of history, once again made us part of its expansion. This kitchen features a highly complete smoke extraction system, which we showcase below.

Smoke extraction at König in Blanes

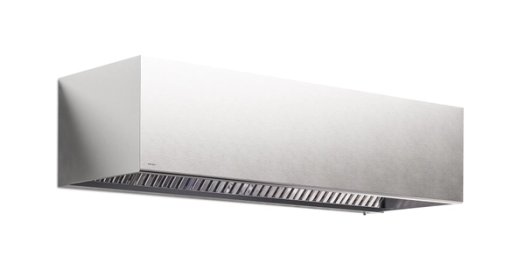

The kitchen at König Blanes is equipped with three Vilak model extractor hoods.

The hoods of this model —like all Morgui extractor hoods— are crafted with meticulous attention to detail, down to the last edge. All models are made from 1 mm thick AISI 304 stainless steel and welded in a single piece up to 6.5 meters long. For easier cleaning and enhanced safety, the hoods feature double folding on all sheet metal edges and have no visible joints or screws.

The three Vilak hoods installed in this project include an air supply plenum through front perforation, 4000K LED luminaires, fire suppression systems, and regulation via frequency converters with three-phase input and output and IP66 protection. Additionally, they feature digital potentiometers for remote control of the frequency drives, housed in stainless steel boxes.

This smoke extraction system operates thanks to two Morgui ventilation units mounted on the restaurant’s rooftop.

We often focus solely on kitchens and extractor hoods, but we tend to overlook a crucial part—the elements that truly make the system work. That’s why we also want to highlight and show images of the rest of the smoke extraction installation.

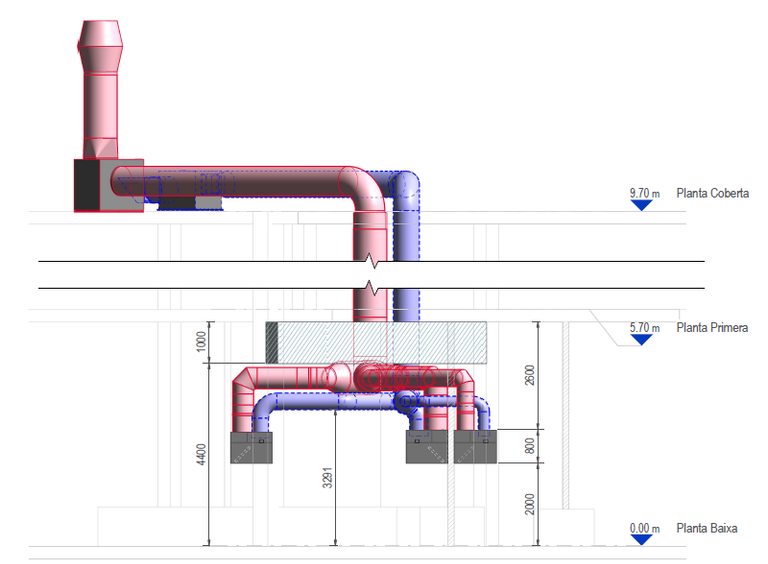

For smoke extraction, a UNIC 400°/2h model 25/13, 7.5 HP Sandwich ventilation box is used, combined with an 800 mm JET-type cowl in two pieces. For air supply, a CUBIC 18/18, 3 HP ventilation box is installed. Both units are three-phase with horizontal outlet, and include IP65-rated tripolar emergency stop switches.

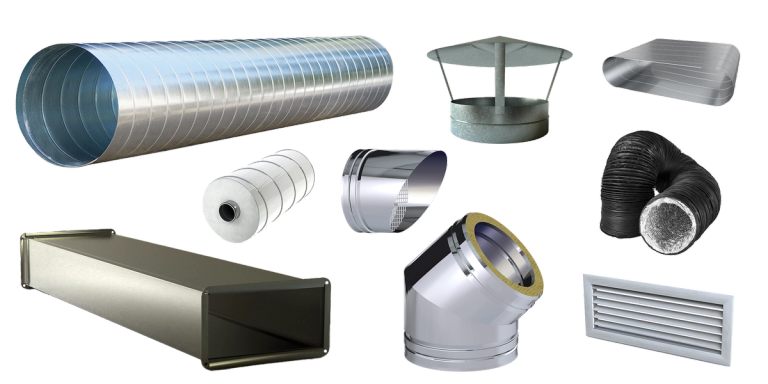

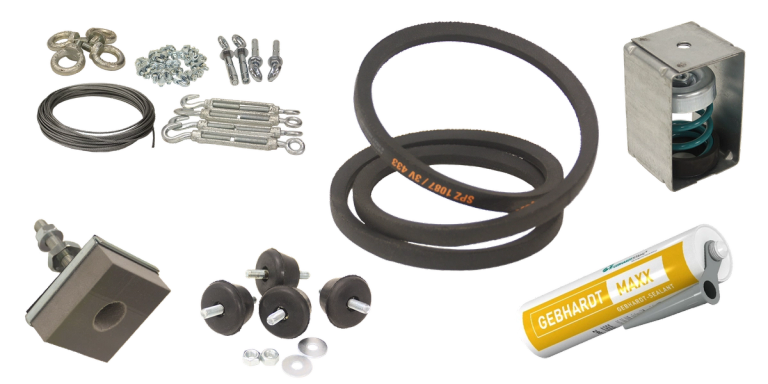

Between the extractor hoods and the ventilation units, there are also many other key components and installation accessories involved—such as EI30 ducting, elbows, tees, splitters, clamps, inspection registers, reducers, hoppers, silencers, filters, and a long list of other essential installation materials.

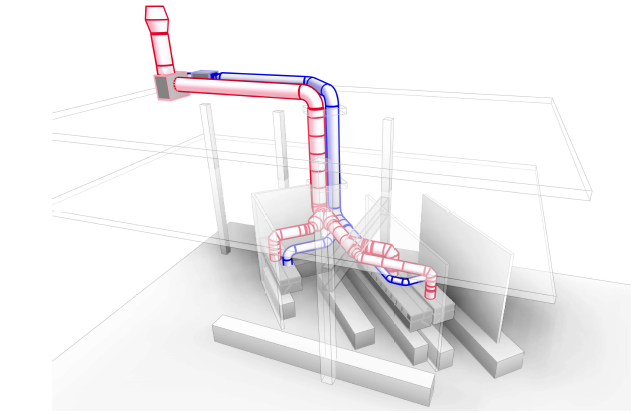

We prepare the required technical documentation and create 2D and 3D plans using SolidWorks, AutoCAD, and Revit.

To achieve effective smoke extraction, it’s not only essential to use quality materials and products, but also to have a solid technical design and accurate calculations for airflow rates, power requirements, duct layouts, and more. These parameters must be carefully considered to ensure the installation is efficient, effective, comfortable, quiet, and convenient for the workers.

At Morgui, we provide this technical service by carrying out a full project study and design, as well as producing 3D plans using BIM methodology with Revit software.