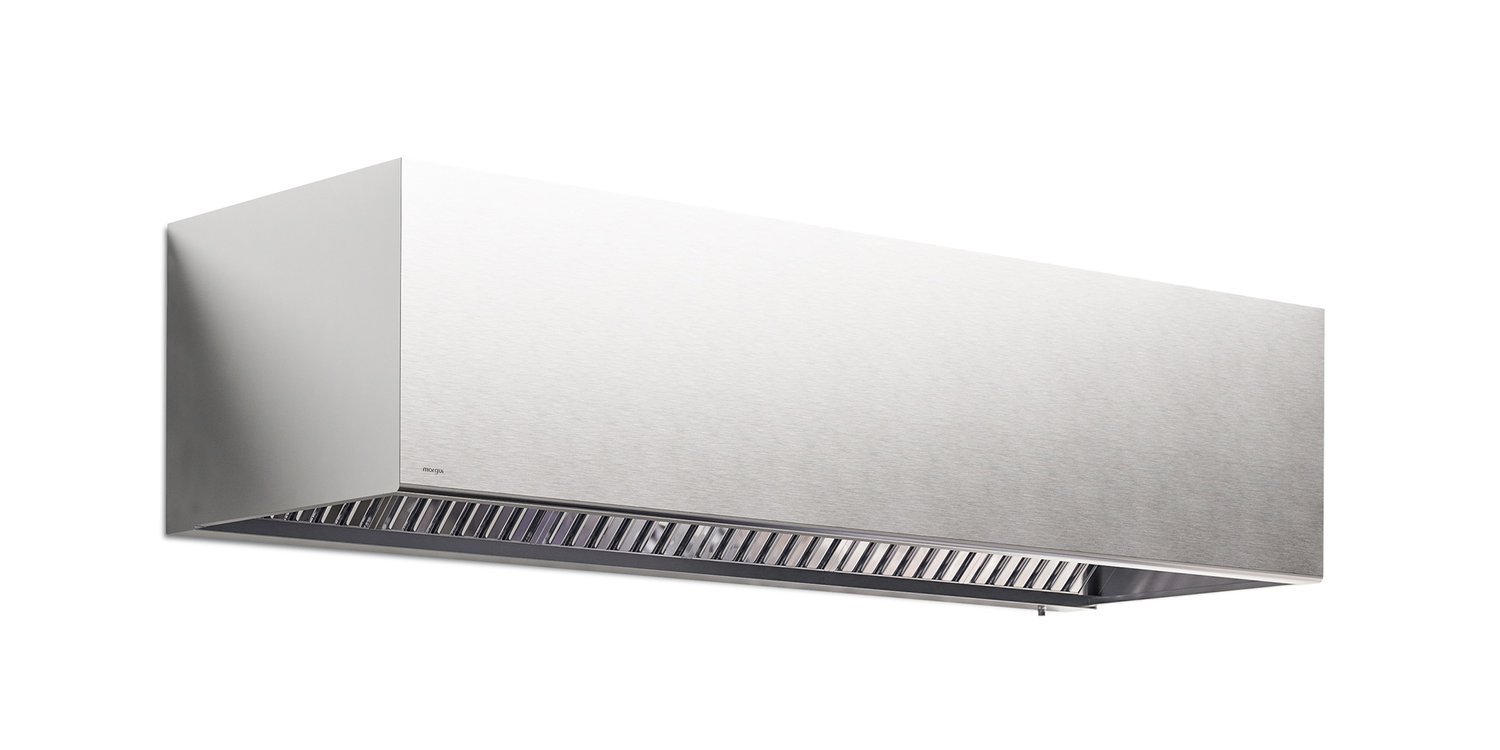

High-efficiency and comfort exhaust hood for industrial kitchens located in extreme climate areas. Its BOOST©️ technology goes beyond conventional air induction.

Available in wall-mounted and central formats.

High-efficiency and comfort exhaust hood for industrial kitchens located in extreme climate areas. Its BOOST©️ technology goes beyond conventional air induction.

Available in wall-mounted and central formats.

BOOST©️ technology injects 60% of the extracted air back into the hood. Maximum efficiency, sustainability, and comfort in a single hood.

Conserva la climatización de tu cocina o local

El aire inyectado queda concentrado en la campana y no compromete al resto de zonas. Si la temperatura exterior es extrema, no te compromete la climatización de tu local.

Maximiza el ahorro energético de tu instalación

Inyectamos el aire exterior dentro de la campana de tal manera que no lo mezclamos con el aire climatizado del resto de la cocina, extrayendo el mínimo aire tratado del local. Esto se traduce en una mejor eficiencia del sistema de climatización/ventilación y, por lo tanto, en un ahorro de consumo y costes.

Garantiza el confort de trabajadores y clientes

El humo que se puede escapar de la zona de cocción es mínimo. Al no aportar aire exterior directamente en la cocina, no sometemos al resto de zonas, sus trabajadores o clientes a corrientes de aire que pueden ser extremas según la temperatura exterior.

Length: according to customer requirements. Depth: minimum 1,600 mm in wall-mounted format and 3,200 mm in central format. Hood height: 500 mm. Recommended plenum height: from 200 to 400 mm.

Wall-mounted or central.

Visible parts made of 1 mm thick AISI 304 stainless steel sheet. Non-visible external tubular structure and ceiling made of galvanized steel.

Fully welded hood in a single piece up to 6.5 m. For larger dimensions, modular construction is used. Manufactured with an external non-visible tubular structure providing greater robustness to the assembly, with no visible screws or joints that could cause dripping or dirt accumulation. All sheet steel edges feature a double fold to prevent possible cuts. The lower edge of the front is rounded to prevent accidental bumps. All extraction plenums include removable regulation dampers. The supply plenum includes internal insulation to prevent condensation. Custom-made constructions available on request, with all types of adaptations for beams, columns, and other structural elements.

Satin finish on all visible stainless steel surfaces. Includes the Morgui logo on the left side of the front. Air supply is provided through perforations on the front. See the customization section for all available configuration and adaptation options.

Morgui hoods are delivered ready for easy installation: with slots and welded threaded plates, and wall or ceiling supports to aid attachment to the building structure. These elements serve as a base, but final installation requires additional materials and fixings depending on each project.

Grease collection channel fully welded around the entire perimeter of the hood and connected to the main tray, at the bottom of the filter collector. The tray includes a drainage plug.

Extraction: stainless steel plate filters AISI 430 polished (thickness = 0.4 mm) 490x490x50 mm. DIN 18869-5:2007-08. Included with the hood.

BOOST©️ System: tubular filters 490x660x80 mm.