Extractor hood designed for capturing water vapour and steam. Its internal labyrinth efficiently filters and enhances the condensation process. Available in wall-mounted and central versions.

Exhaust hoods | Morgui

Vapor Hood

- Suitable for washing areas

- 100% STAINLESS STEEL AISI 304

- Optional LED lighting fixtures

The ideal solution for extracting vapours from dishwashers, wash tunnels, bain-marie cooking areas, and other applications that generate steam.

Main features

Extractor hood designed for capturing water vapour and steam. It features a triple internal labyrinth that creates multiple accelerations and 180° turns, improving the condensation of vapours.

Length: according to customer requirements. Depth: minimum 1,000 mm. Hood height: 400 or 500 mm.

Wall-mounted or central format.

Visible parts made of 1 mm thick AISI 304 stainless steel sheet. External non-visible tubular structure made of galvanized steel.

Hood fully welded in a single piece up to 6.5 m. Built with an external non-visible tubular frame that provides greater strength to the whole unit, with no visible screws or joints that could cause dripping or dirt accumulation. All edges of the steel sheets are double-folded to prevent cuts, and the lower edge of the front panel is rounded to avoid accidental impacts.

It features a triple labyrinth and a cooling plate inside that act as filtration and condensation elements. It also includes two built-in fans that drive the steam through the condensation circuit and subsequently allow air evacuation.

Custom-built on request, with all types of adaptations for beams, columns, and other structural elements.

Satin finish on all visible stainless steel surfaces. Includes the Morgui logo on the left side of the front. Air supply is provided through perforations on the front. See the customization section for all available configuration and adaptation options.

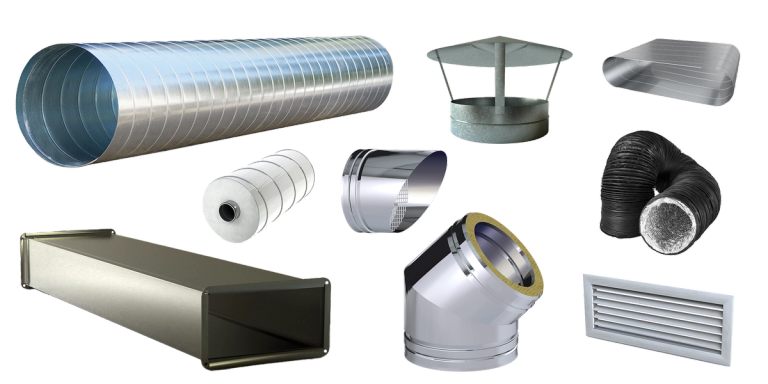

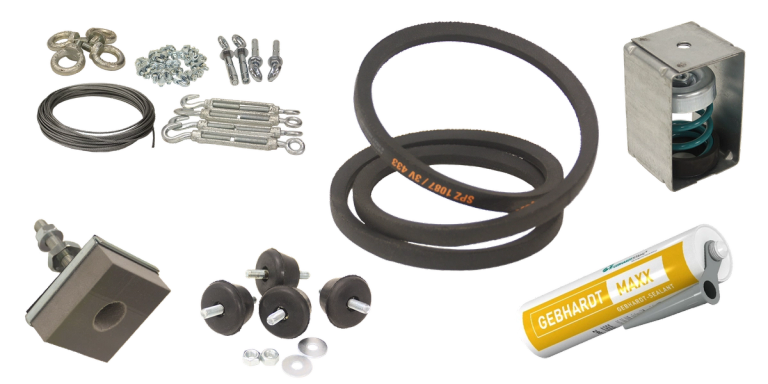

Morgui hoods are delivered ready for easy installation: with slots and welded threaded plates, and wall or ceiling supports to aid attachment to the building structure. These elements serve as a base, but final installation requires additional materials and fixings depending on each project.

Grease collection channel fully welded around the entire perimeter of the hood and connected to the main tray. The tray includes a drainage plug.